* Although a single cylinder engine might work well, I believe that enough cylinders to allow the induction pressurizers to be contributing near 100 percent of the time would work out the best.

* The Lullen-Cycle has near totally discrete intake and exhaust charges because their is no overlap of valve open time and also virtually to combustion chamber to be scavenged or allow for dilution.

* In most positive displacement motors a piston in a cylinder acts as the compressor. It might seem counter-intuitive to use a sort of fan to provide all of the compression needed but that is exactly what jet engines do and with compression ratios that are higher than an Otto-cycle can endure with premium pump gasoline.

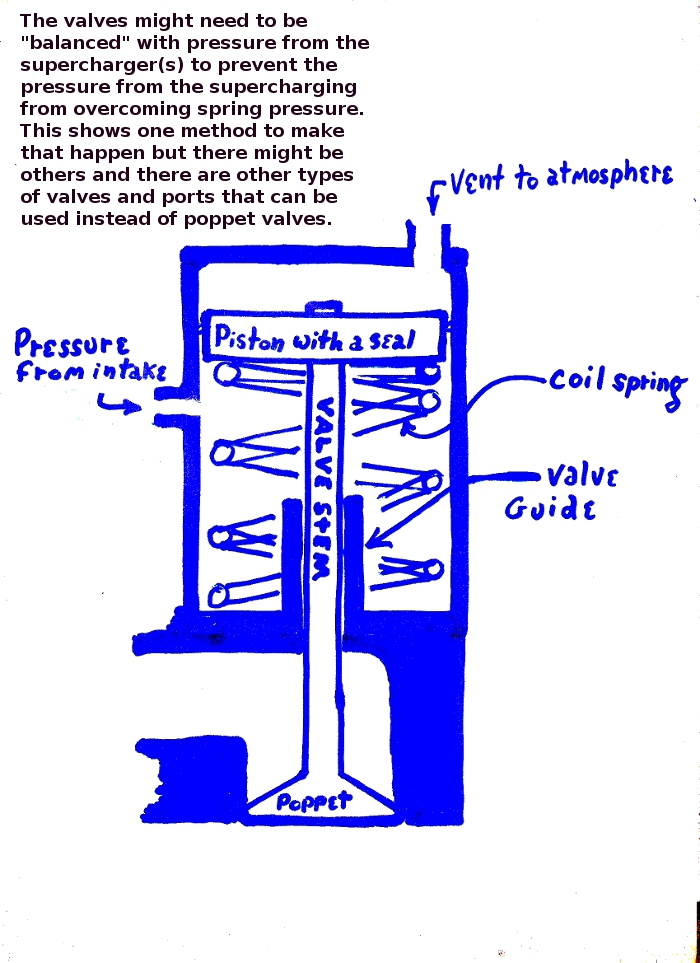

* Valves and Springs, Many different valve assembles are usable and I tend to think in terms of the common poppet valve but perhaps that's too restrictive. Rotary valves might prove to be better but back to the poppet valves, I think they would be the easiest to work with and lend themselves well toward creating a near zero dead-space between the piston and the head when the piston is at top dead center.

*In some situations such as the simple Lawnmower type of motor I describe in this site some simple valve return springs might suffice but some other arrangement such as

desmodromic valves or a pressure balanced design might work out better. A balanced poppet design counters the the force that intake pressure exerts on the intake valve and tending to open it and allow an intake charge into the cylinder when it is not appropriate. For a sketch of such a valve click on the picture to the right.

* "Inching phase" This is a situation where just air pressure is introduced into the cylinders to make the motor turn or have a tendency to turn (static torque). Basically this would be to be using the motor as an air driven motor and a source of air pressure would have to be available. (Possibly a supercharger with an option to be electrically driven). This could also serve as a way to make the engine rotate reverse of normal to give reversing possibility in a vehicle if there is no reverse gear provided. "Hybrid" potential is possible with a system such as this too if a pressure reserve method such as a pressure vessel were to be incorporated into a system too.

* Compression ignition or "Diesel" capability. There are ways I believe this can be done. One is with a cam that will force the piston back up somewhat after it is filled and cause a mixture already close to igniting to ignite but that would probably restrict rotational speed. Another way would be via a rapid release of relatively high pressure air into the cylinder at the right time or even a controlled "Hot bulb" setup.

* Given the possibilities of pirating some air pressure from the intake system, pneumatic cylinders, diaphragms, logic circuits, suspension aids, power assist items and motors could replace many things that currently using electricity, "vacuum" and Hydraulic pressure. There is even a possibility to use compressed air as a means to cool air for air conditioning using no other working fluid other than air itself.

Here's a link to a site that specializes in this kind of thing.

* I imagine that a Lullen-cycle motor could be made to work well with a "mono-propellant" of some sort or even propellants that need to be combined. These sorts of adaptations could be used in applications where air is not available such as in space or underwater.

* In aiding the piston's outward movement the opening valve(s) could be used as "piston pushers" as they will be opening at the same time that the piston needs to move outward anyway. Care would need to be taken to design this as to not cause valve binding and other distortions or problems.

© 2010 - 2011 by Walter E. Parrish. All Rights Reserved