Consider this

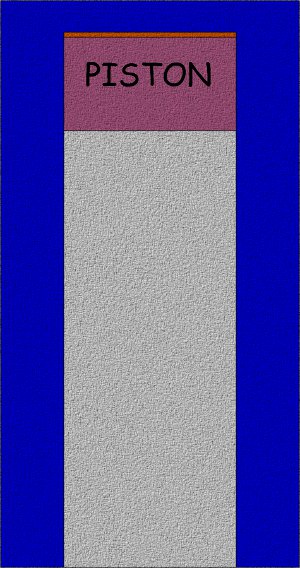

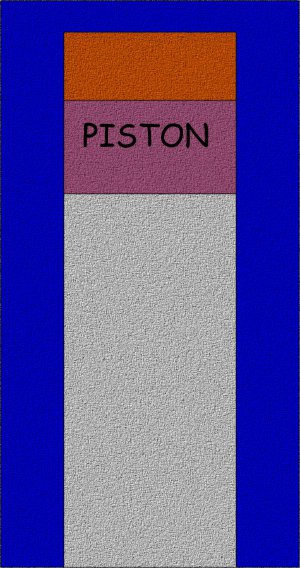

If a relatively small volume of fuel/air mix (represented by the orange section above the pistons in these illustrations) were to be ignited such as in this illustration then the piston would be driven by the expanding but only so far before the gasses cool and once they cool enough then the piston would be coerced back some distance by atmospheric pressure.

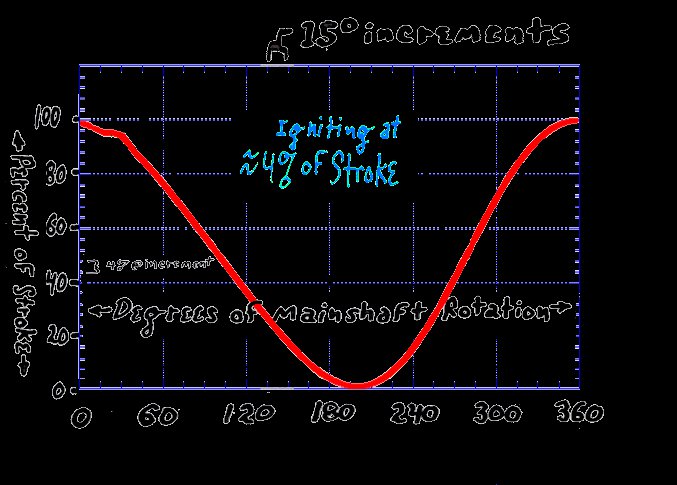

Because most motors have a combustion chamber built in that is about a tenth of the volume displaced by the sweep of the piston. The ability to do that little trick is not possible unless an extremely long stroke compared to bore were to be used. With a Lullen-cycle design it's entirely different. At low power demands especially, the exhaust gasses might be quite cool due to the difference of expansion being greater than what is normally encountered in other motors.

Relatively mildly compressed fuel/air mix taking up much volume. Although this might be representing an otto cycle with a 10:1 compression ratio the compression ratio is offset when air has been stretched thin or at lower than atmospheric pressure before the compression stroke. (Such as is the case in conventionally throttled motors.)

Although the fuel air (shown as being orange) in both illustrations here have the same amount of fuel and air and also in the same proportion the one on the right will get more useful/kinetic energy from the mixture and as a result there will be less heat given to the atmosphere via hotter exhaust gasses.

A cycling curve more or less representing what is being shown above. The bigger issue here isn't any exact numbers but to show the opportunity for a much greater expansion ratio by the Lullen-Cycle than what is provided by the other processes now in common usage.

The same amount of fuel/air mix exist in both examples below. One will deliver more kinetic energy to the piston and the other will deliver more energy to the atmosphere as heat.

Light "throttle" extreme comparison.

To "throttle" a Lullen-Cycle we can keep the fuel/air mix density as high but close the inlet valve earlier and then ignite the mix earlier as well too. The combination of high density and a high expansion ratio should increase efficiency over conventional throttling by quite a bit.

© 2010 - 2011 by Walter E. Parrish. All Rights Reserved